Solid lubricants vol.4: Ceramic additive (hBN)

固態潤滑劑4:陶瓷氮化硼添加劑(hBN)

In our last article we compared MoS2, Teflon and graphite as solid lubricants. Now it’s time to talk about the cream of the crop: ceramic (boron nitride). Also called “white graphite”, the ceramic powder of hexagonal boron nitride is the best dry lubricant in the oil additive business. Keep reading to discover why.

在最近的文章我們比較了固態潤滑劑MoS2, Teflon及石墨。現在是來聊聊陶瓷以作為結尾:陶瓷(boron nitride氮化硼)。也就是所謂的”白石墨”,在機油添加劑的產業裡,六角片狀氮化硼陶瓷粉末是最佳的乾式潤滑劑。

繼續看下去就會發現原因。

Performance(表現)

When we talk about solid lubricants, we refer to materials capable of reducing friction between two surfaces. The main advantage of having them mixed in with our oil is that they significantly reduce wear while improving our oil’s durability.

當我們談論到關於固態潤滑劑,我們所指的是這個物質能夠降低兩個面之間磨擦。將它們與我們機油混合後主要的優點是能顯著的減少磨損,也就是能夠提升我們機油的耐受度。

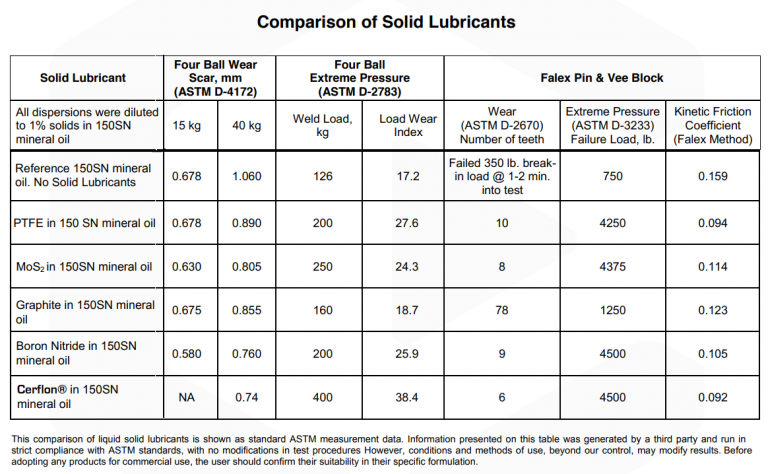

After analysing the other 3 additives (PTFE, MoS2 and graphite), we have probably already said everything about their differences and uses. On this occasion, we will let numbers speak for themselves.

在分析其他3種添加劑(PTFE, MoS2 及 graphite)後,我們已經大致說到關於它們的區別及應用。在這個時候,我們想讓數字來說話。

Source: Cerflon site

As we descend in the table we see how each material generally improves on the results of the previous one. When we get to Boron Nitride, we notice that this lubricant outperforms the previous additives in every aspect. Ceramic easily wins the wear scars (D-4172) and extreme pressure (D-3233) tests. Moreover, it gets close to both PTFE and MoS2 in the extreme pressure (D-2670) and kinetic friction (Falex) tests.

當我們沿著表格看下來時,可以看到各種物質的結果相較上一個更好。當我們看到氮化硼,我們注意到潤滑油的各項表現都比之前的添加劑要傑出。陶瓷在磨損測試(D-4172)及極壓測試(D-3233)很容易就勝過其他添加劑。此外,在極壓測試(D-2670)和運動摩擦(Falex)測試和PTFE及MoS2結果接近。

However as you can see, the winner is Cerflon, mentioned in the PTFE article, with an overall excellence.

然而你會看到冠軍是Cerflon,在PTFE的文章中有提到整體來說是優異的。

However, as always, we must use perspective. As we have pointed out in our Technology section, the problem with Cerflon, and PTFE, is their operational temperature range. While ceramic can withstand more than 1.000ºC, Cerflon maxes out at 300ºC.

但是,如同以往所說,我們必須使用要客觀。正如同我們在我們的技術部份所提到的,Cerflon及 PTFE的問題就是它們工作溫度範圍。陶瓷可承受的溫度可超過1.000ºC,但Cerflon最高只到300ºC。

Ceramic oil additive in Xenum

(Xenum中的陶瓷機油及添加劑)

As with graphite, the potential of this additive made us believe that the perfect oil hadn’t been designed yet. That is how the VRX range was created.

If you are about to change your oil, our recommendation is to go for the VRX ceramic oil range. Currently we have 5W30, 5W40 and an exclusive 7.5W40.

對石墨來說,添加劑的潛力讓我們相信最完美的添加劑尚未被創造出來。這也就是為何會創造出VRX系列。如果你正要更換機油,我們推薦使用VRX陶瓷系列機油。

目前我們有5w30,5w40及獨特的7.5w40。

It’s also worth mentioning our VRX 500 has a -41% friction reduction, according to a leading certification company. The components present in VRX 500 are in all the VRX range, so they show similar results.

另一件很值得一提的是依據一間可靠的公司表示,在我們的VRX500能減少41%的摩擦係數。VRX500的這結果也存在於所有VRX系列,所以這些產品都有相同的效果。